Description:

This is the second project that I produced on behalf of another client. This was for Stahmer Engineering, a Queensland business that specialised in designing and manufacturing automated machines for the manufacturing and resources industries, in particular CNC lathes. This was the type of machine that I was commissioned to design, for another company that supplied equipment for constructing oil and gas pipelines.

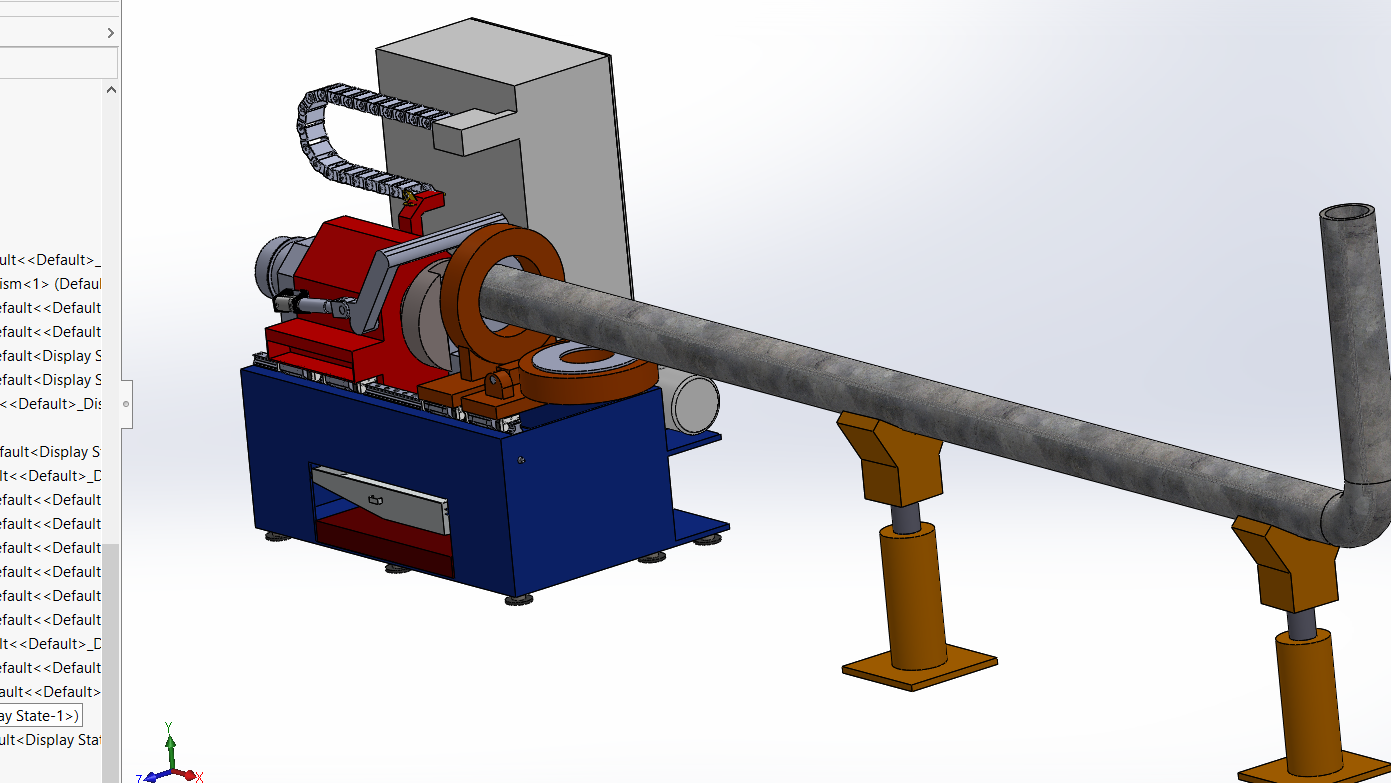

This lathe was designed to machine the ends of each section of pipe as it was being installed, to fit to each section. The key difference was that the spindle and tip assembly would rotate around the job as it was being machined, rather than the job being rotated as for most lathes. This was to ensure that pipes that weren’t straight, especially with ninety-degree bends in them, could also be machined, which is not possible with a typical lathe due to the excess movement and forces of the extra material moving around as it is machined.

I translated the rough analogue sketches into 3D CAD models using Solidworks, to then transfer to orthographic views and assembly drawings, to present to prospective clients. As well as modelling a multitude of individual components and subassemblies, across seven iterations of the machine, I also sourced CAD files of off the shelf components and subassemblies from sites such as GrabCAD and the BOSCH/Rexroth sites to make the design more realistic and save time.

Unfortunately, this project was cut short after only two months due to the pandemic and lockdowns taking effect, and the project being cancelled after the external client this was being designed for requested the project be put on hold. Overall, I enjoyed this project as it taught me how to bring a design from an initial concept into reality, as well as designing for external clients, plus designing a product for heavy industries and in a predominantly mechanical engineering environment.

Client:

Stahmer Engineering

Project Timeframe:

February – April 2020

Project/Product:

CNC Lathe